The packaging industry is experiencing a period of unprecedented growth, driven by e-commerce booms, changing consumer habits, and a relentless demand for faster, more efficient production. This surge in demand has placed immense pressure on packaging equipment manufacturers. Amidst this competitive landscape, one often-overlooked component is gaining critical attention: the gear motor. Packaging equipment performance – including speed, accuracy, and reliability – is inextricably linked to the performance of the gear motors within. Manufacturers are increasingly prioritizing gear motor selection and optimization to meet the evolving demands of the industry, particularly in the context of sustainability, automation, and the "just-in-time" supply chain initiatives that are currently dominating business strategies.

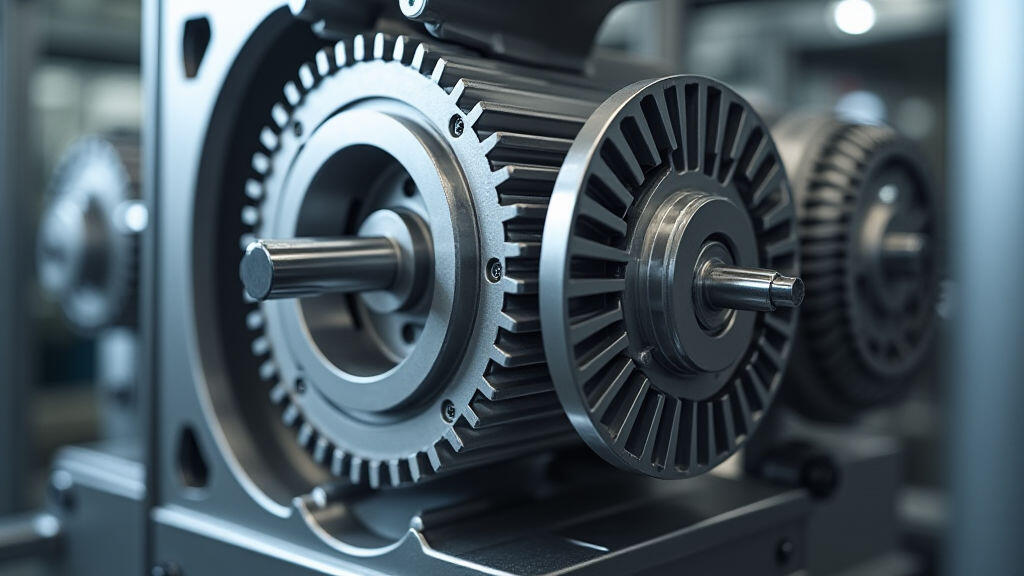

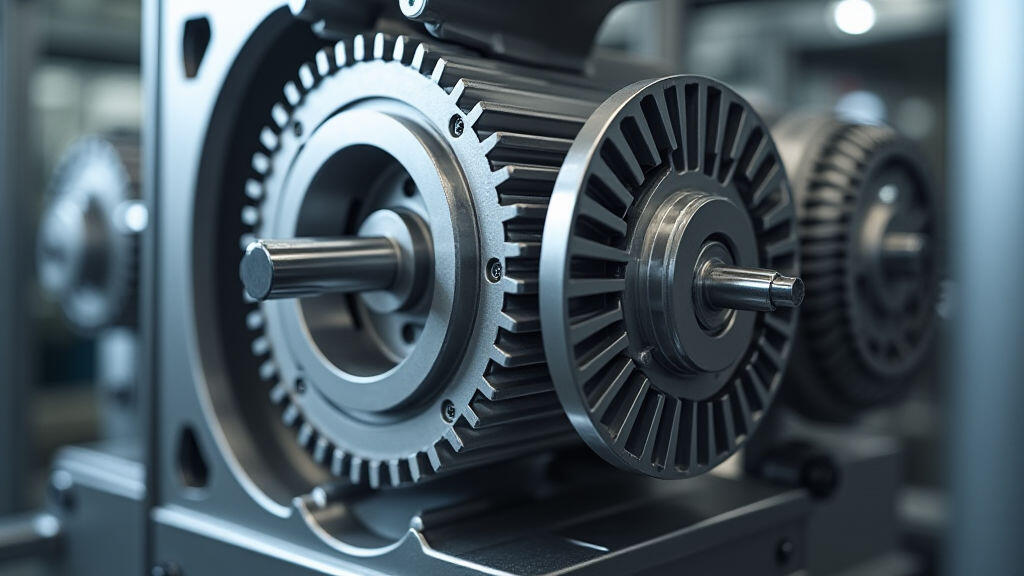

Gear motors are the workhorses behind countless packaging processes. From conveyors and robotic arms to filling machines and sealing equipment, these motors provide the precise torque and speed required for a myriad of tasks. Their ability to convert rotational motion into controlled linear or rotary motion makes them indispensable for achieving the high levels of precision and efficiency that define modern packaging lines. A poorly performing gear motor can lead to inconsistent product handling, reduced throughput, increased downtime, and ultimately, financial losses for packaging companies.

Consider a high-speed filling machine, a staple in modern beverage production. The gear motor responsible for delivering precise volumes to each container needs to operate with unwavering accuracy. Any deviation in speed or torque can result in overfilling or underfilling, leading to product waste and quality control issues. Similarly, robotic arms used for palletizing boxes require gear motors with robust performance characteristics to handle the repetitive demands of high-volume operations without compromising speed or precision.

The packaging industry is undergoing a significant transformation, and this evolution is directly impacting the requirements for gear motors. Several key trends are driving the increased focus on performance optimization:

1. Automation and Robotics: The relentless push towards automation continues to accelerate. Robotic systems are increasingly integrated into packaging lines to improve speed, reduce labor costs, and minimize human error. This integration demands gear motors capable of operating within tight, precisely controlled environments. Specifically, requirements include high precision, low backlash, smooth operation, and compact designs. The rise of collaborative robots (cobots) further adds to the complexity, requiring motors that can seamlessly integrate alongside human workers.

2. Sustainability and Energy Efficiency: Sustainability is no longer a niche concern; it's a core business imperative. Packaging equipment manufacturers are under increasing pressure to design energy-efficient machines. Gear motors play a significant role in energy consumption, and manufacturers are actively seeking motors with improved efficiency ratings. This includes exploring advanced gear designs, optimized lubrication systems, and the integration of energy-recovery technologies. The growing emphasis on circular economy principles is also influencing gear motor choices, with manufacturers considering materials and manufacturing processes that minimize environmental impact.

3. "Just-in-Time" (JIT) Manufacturing & Flexibility: The JIT manufacturing philosophy, emphasizing minimal inventory and responsiveness to changing customer demands, requires packaging lines that can quickly adapt to new product sizes, shapes, and packaging formats. Gear motors need to offer a wide range of speed and torque options to accommodate this flexibility. Furthermore, rapid changeover times necessitate motors that can operate reliably under varying loads and speeds. Manufacturers are exploring gear motor solutions that can be easily configured and integrated into modular packaging systems, allowing for quicker adjustments.

4. Data-Driven Optimization & Predictive Maintenance: The Industrial Internet of Things (IIoT) and data analytics are transforming equipment maintenance. Packaging equipment manufacturers are leveraging sensors and data-driven insights to monitor gear motor performance in real-time. This allows for predictive maintenance, identifying potential problems before they lead to downtime. Gear motor manufacturers are responding by providing motors with integrated sensors that can monitor parameters such as temperature, vibration, and current draw. This data is then used to optimize motor performance and predict potential failures.

To meet these evolving demands, gear motor manufacturers are innovating and incorporating advanced technologies. Some of the key trends include:

Companies like MES-Drive are at the forefront of this performance optimization movement. MES-Drive offers a comprehensive portfolio of high-performance gear motors specifically designed for the packaging industry. Their motors are engineered for:

By partnering with MES-Drive, packaging equipment manufacturers can ensure their equipment incorporates the most advanced and efficient gear motor technology.

The increasing focus on gear motor selection and performance optimization is a critical trend in the packaging industry. Driven by automation, sustainability, JIT manufacturing, and data-driven operations, manufacturers are demanding higher efficiency, greater reliability, and improved control from their gear motor suppliers. Technologies like planetary gear motors, BLDC motors, and advanced material science are leading the charge. Companies like MES-Drive are playing a pivotal role in providing innovative solutions that enable packaging equipment manufacturers to meet these evolving challenges and maintain a competitive edge. As the demand for efficient, sustainable, and flexible packaging solutions continues to grow, the importance of optimized gear motor performance will only increase. Investing in these advancements is not just about improving current performance; it's about building a future-proof packaging line capable of adapting to the ever-changing needs of the global market and contribute to a more sustainable and efficient supply chain.

Leave A Reply

Your email address will not be published. Required fiels are marked